Grinding wheels with ultra-hard diamond or CBN cutting materials are used for grinding ceramics, tungsten carbide and hardened steel. In order to achieve increased precision and efficiency in the grinding process, the use of grinding wheels with sintered metal binding is preferred.

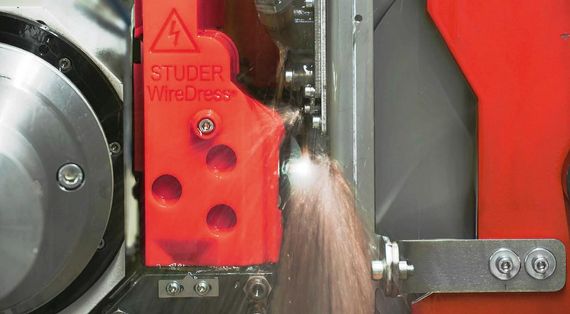

WireDress® - The revolutionary dressing unit

However, their use has previously only been of limited value, as metallic bonds can only be dressed to a very limited extent and the process is costly in terms of time and resources. One option for dressing such grinding wheels that has proven highly effective in practice is the use of external working machines. However, the use of such external work machines necessitates handling and logistics steps that interrupt the grinding process and thus generate unnecessary additional costs for the operators of such systems. For this reason, the dressing of complex or fine profiles has not been economical to date.

Fritz Studer AG, established in 1912, is a market and technology leader in universal, external and internal cylindrical grinding as well as noncircular grinding. With around 23,000 delivered systems, the STUDER name has been synonymous with precision, quality and durability for decades. With a complete bespoke solution for every grinding operation, the customer also benefits from our knowledge and expertise in all aspects of the grinding process. For decades, the STUDER logo has been synonymous worldwide with delivering first-class results. To ensure that this success extends into the future as well, Fritz Studer AG is continuously working on new innovations for grinding. This has led STUDER to develop a dressing unit to dress metal-bonded grinding wheels in the grinding machine. This eliminates the external handling steps as well as logistics tasks for the operator, making dressing of metal-bonded grinding wheels economically feasible.

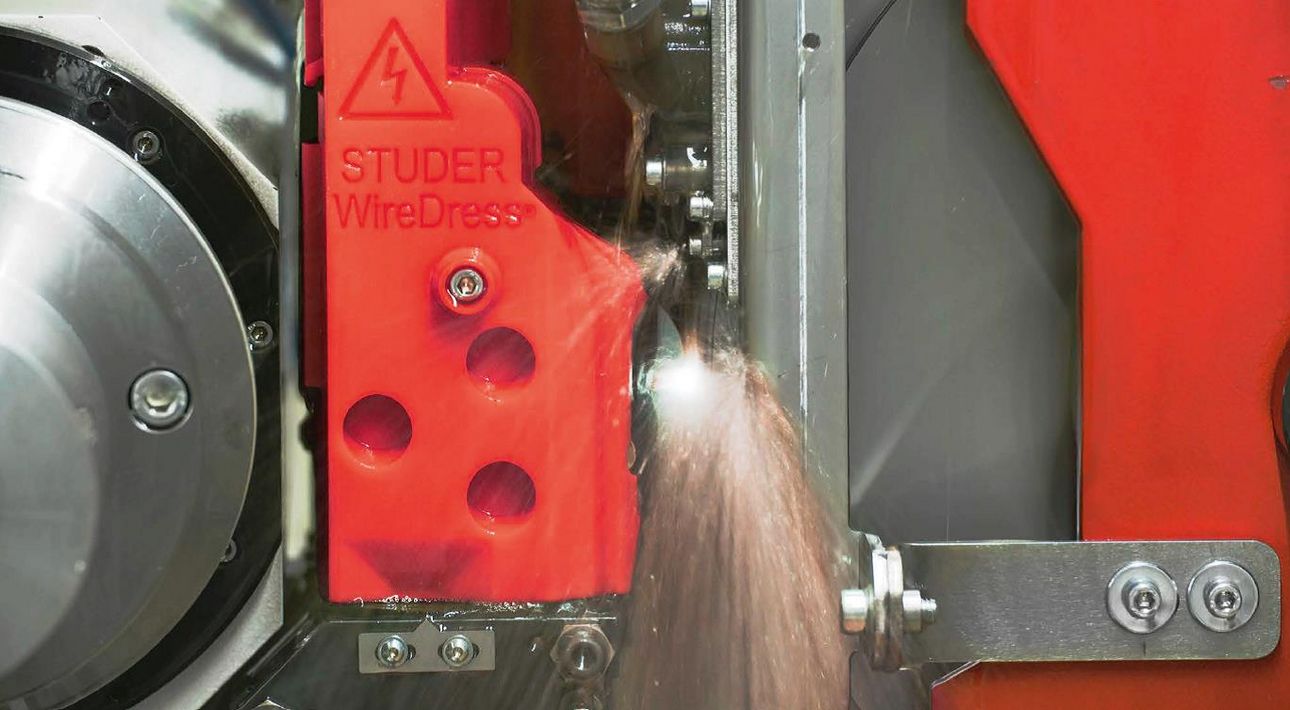

One of the biggest challenges was the integration of the newly developed dressing unit into the available working space of the finished series grinding machines. This means that the dressing unit must be able to be integrated into systems already in use by the customers. Due to the working principle of the dressing unit, which is similar to a small wire eroding machine, the components must be made of non-conductive materials. At the same time, the components to be developed must have increased rigidity and resistance to mechanical and chemical wear.

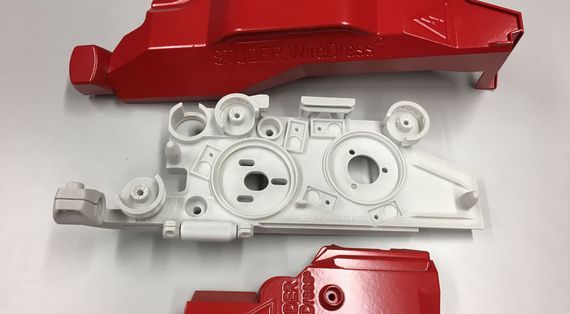

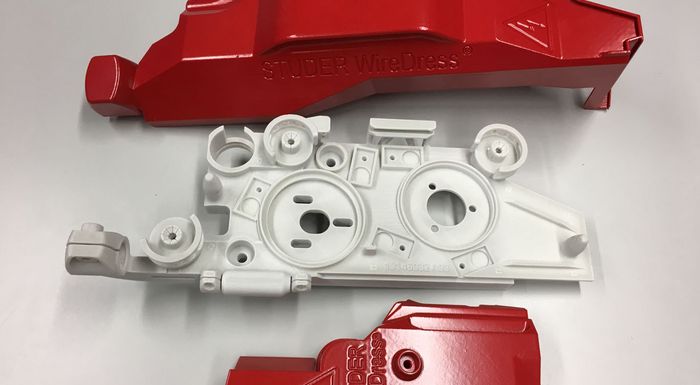

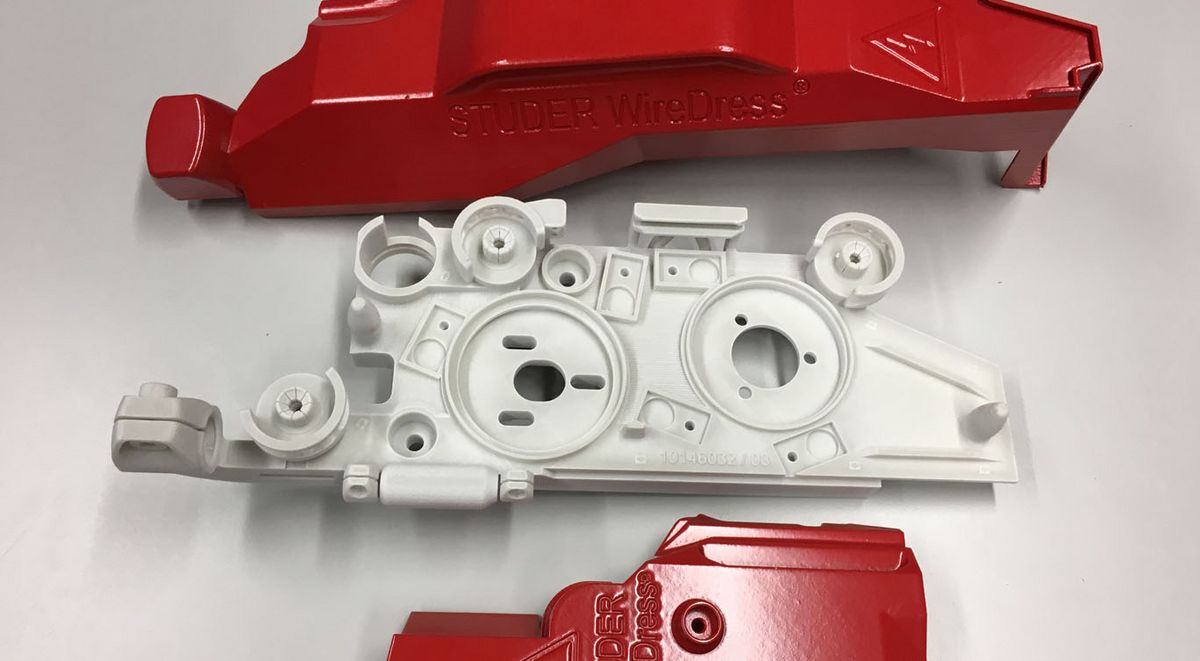

An attempt was initially made to produce the unit in a conventional way. It quickly became clear that not all functions could be implemented in the available space using a conventional design. The space was simply too small. A new approach had to be found. Together with Irpd AG, the Competence Centre for Additive Manufacturing (AM) of the UNITED GRINDING Group, the designers were able to use the strengths of additive manufacturing – in particular Selective Laser Sintering (SLS) – and incorporate them into their new design. This technology has opened up many new possibilities in terms of design freedom and functional integration. A much narrower design of the complete assembly could be achieved. During the development phase, the short delivery times for SLS components proved a difference maker in terms of component changes and generating competitive advantages. Almost all components of the dressing unit are produced additively from plastic.

Design challenges and opportunities

One of the biggest challenges for the engineers was surely reorienting themselves to the different factors involved with conventionally designed components and those associated with additive design. An AM-compliant design allows many new possibilities for subsequent component design. In order to take advantage of these possibilities, the designers had to rethink their plans. Functions that are inconceivable and unavailable to conventional design are now possible. An understanding of how such designs might look and compliance with all other important requirements in an AM compliant design were communicated at a multi-day ThinkAddtive® workshop at Irpd AG.

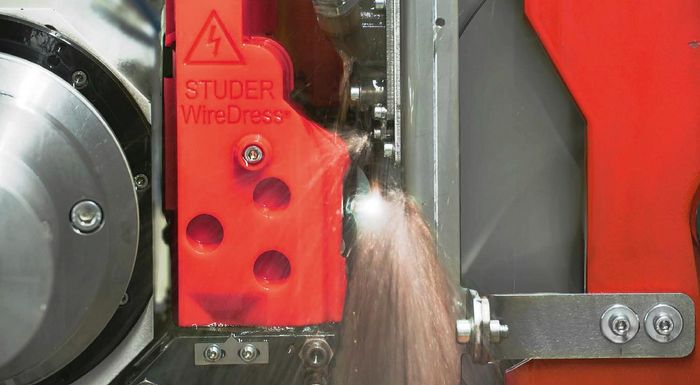

The DuraForm HST base plate illustrates the potential for additive production, especially with regard to a very high degree of functional integration. The combination of multiple components into one assembly contributes significantly to cutting assembly costs. Furthermore, a flow-optimized coolant line has been integrated into the HST base plate, which constantly and evenly moistens the wire during the process. The mineral fibers in the HST material contribute to a significant increase in strength compared to the conventional material PA12. This makes it possible to manufacture dimensionally stable components with strong rigidity. To protect against mechanical and chemical wear and ensure long component life, each component undergoes a special surface treatment.

The strengths of AM technology were also evident in the coverings used to protect the installed components. The shape of the cover can be perfectly adapted to the interior of the grinding machine. This makes it easy to adjust the covers to different grinding machines without the need to change other components such as the base plate. Honeycomb structures were used on the inside of the covers to achieve high rigidity despite very thin wall thicknesses. Important warning symbols could also be factored into the design of the component and displayed directly on the cover. This eliminates the need to affix the warnings afterwards and prevents the warning from being removed or damaged by the wet conditions in the grinding machine. To protect the plastic against the coolant in the grinding machine, the surface is sealed before completion.

Project success

Thanks to SLS technology and the associated possibilities of an AM compliant design, the STUDER WireDress® system was developed for full integration into the cylindrical grinding machine and its control system. This eliminates the hassle of dismantling and resetting the grinding wheel during reassembly. The system allows the operator to first dress grinding wheels at full working speed in the system, i.e. have them profiled and sharpened. This also gives the grinding wheel a strong cutting ability with a high grain separation. Overall equipment effectiveness (OEE) was significantly increased and grinding performance boosted by more than 30%. The project would not have been possible in this form without the use and benefits of SLS technology. The SLS components are currently in serial production and are successfully being used by many customers.